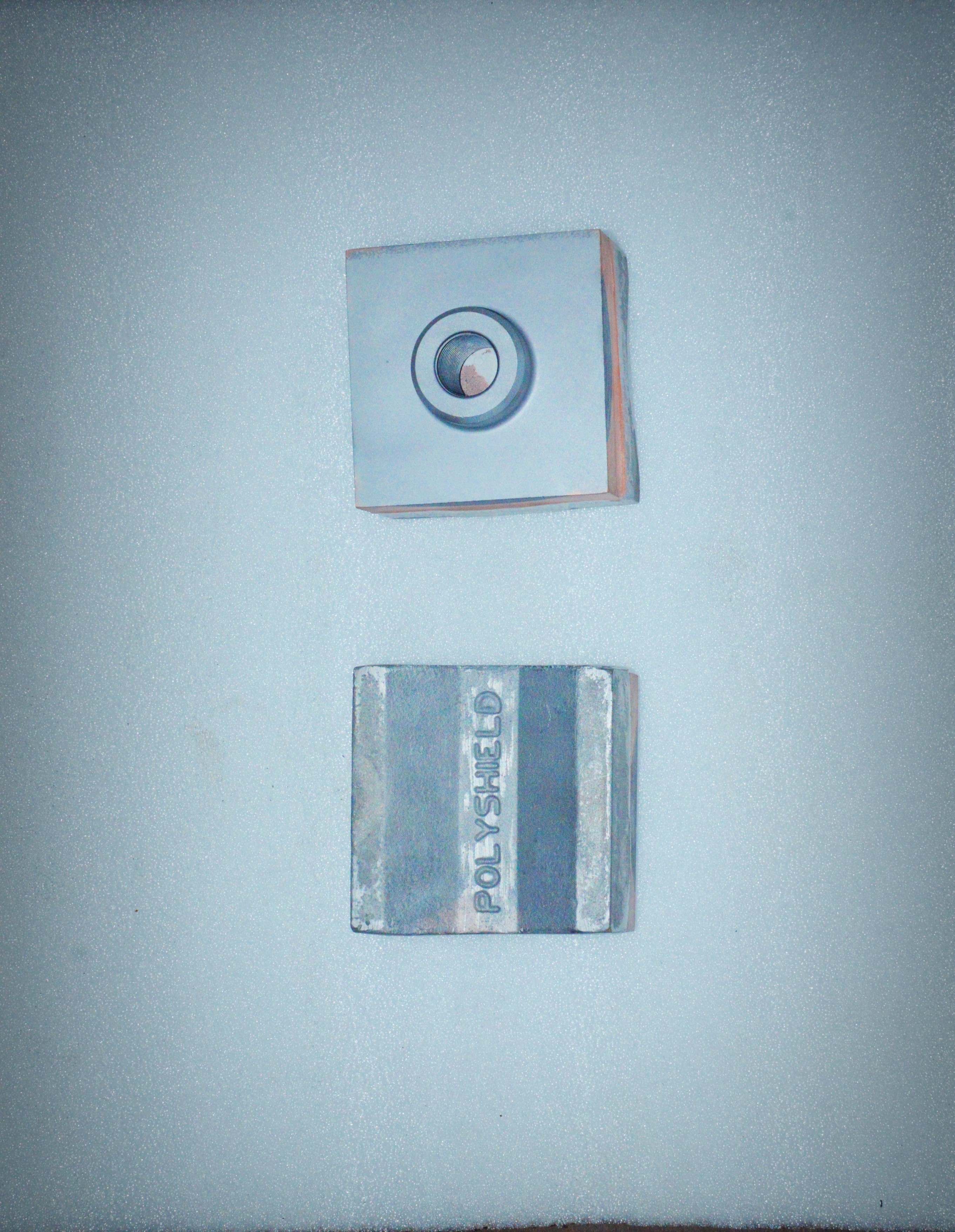

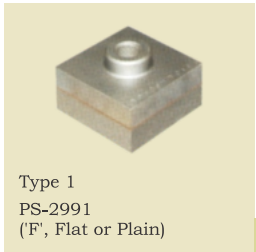

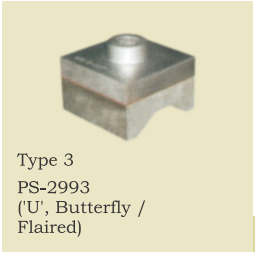

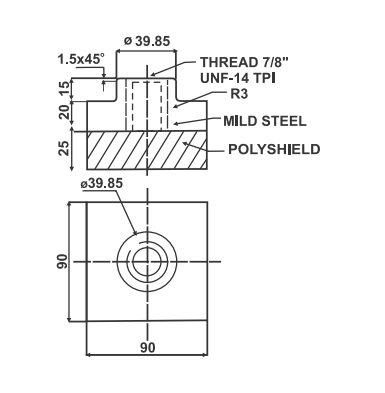

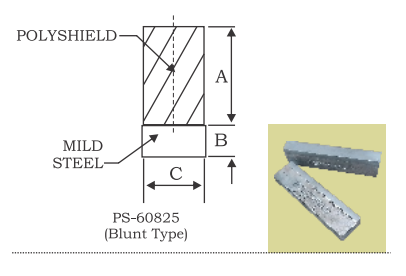

Detachable Hammer Tips

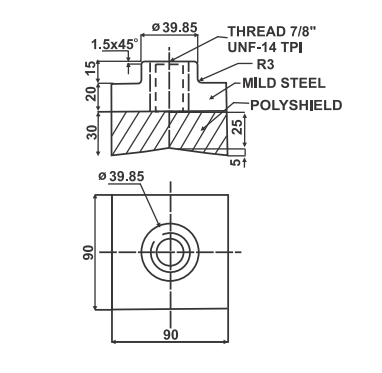

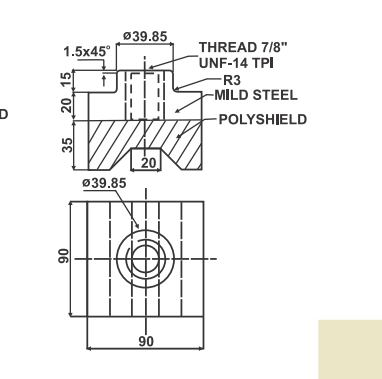

The comprehensive range of POLYSHIELD detachable hammer tip manufactured by us is known for excellent impact & abrasion resistance properties & enhanced service life. These are bi-metallic composites having 700 bhn hardness and are bolted to the hammer shank using high tensile bolt. our range of hammer tips is available in various standard & custom-built sizes.

Know in depth

The extensive selection of POLYSHIELD detachable hammer tips manufactured by our company is renowned for its outstanding impact and abrasion resistance properties, which significantly contribute to an extended service life..

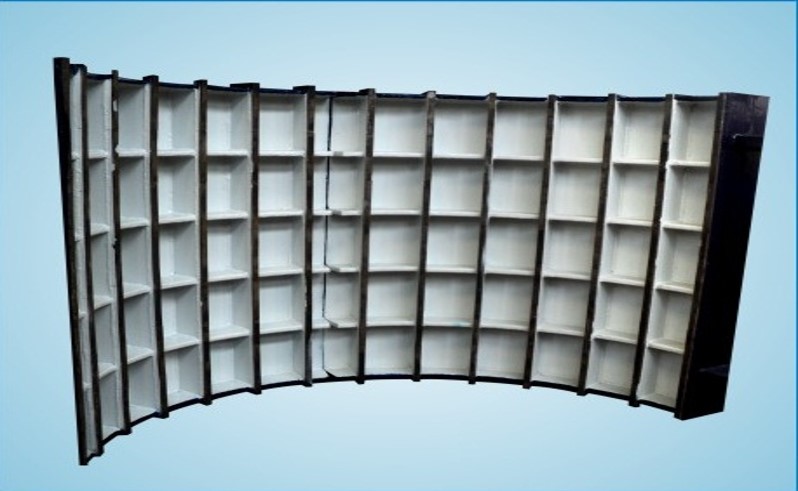

Cane Knife Edges

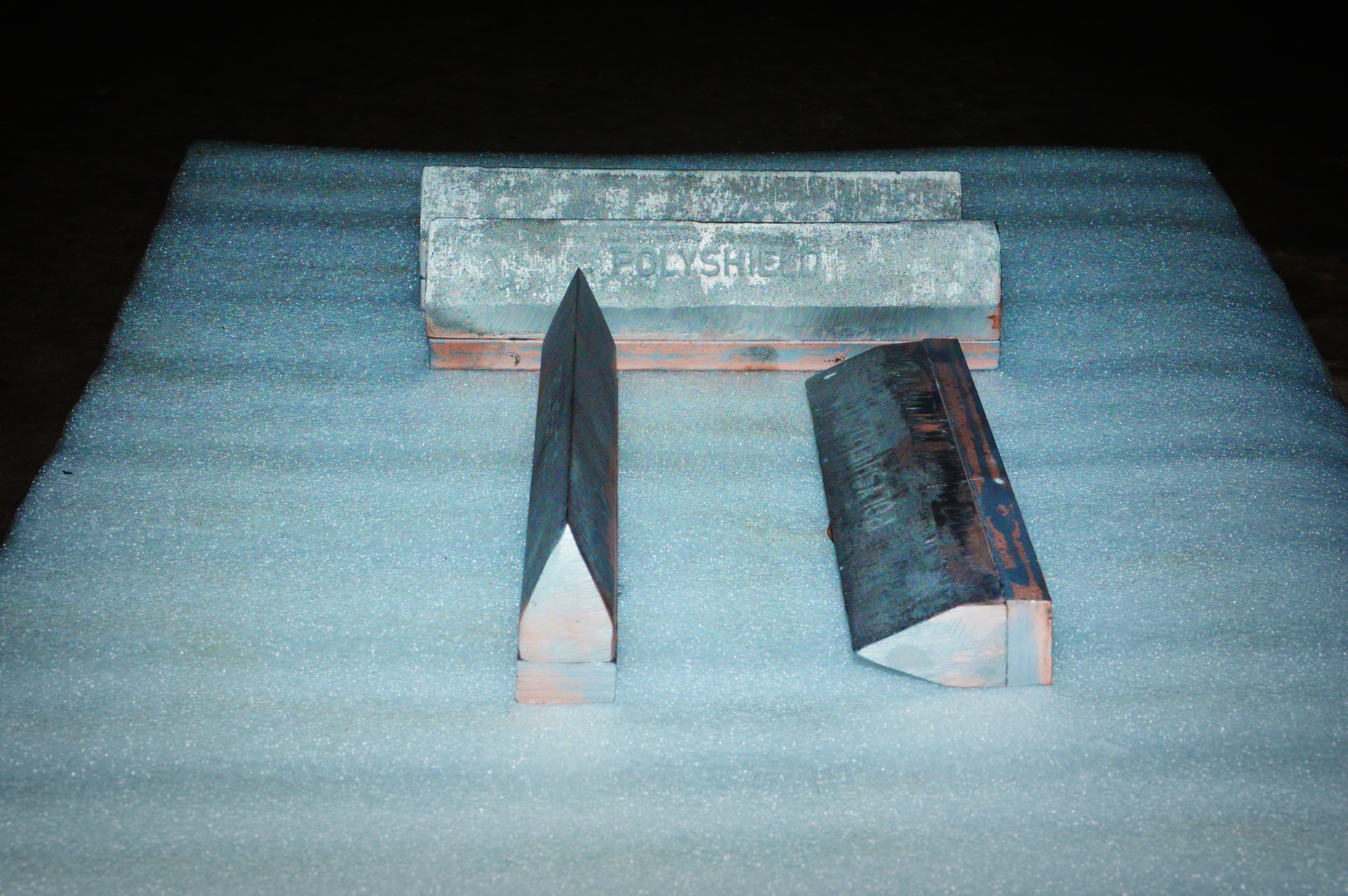

Before the advent of the Shredder, cane knives were the only means of preparation & hardfaced knives were used for primary/secondary & main knifing of the sugar cane.

POLYSHIELD Knifes Edges have now mostly replaced the conventional hardfaced knives due to their versatility. The abrasion & impact resistant properties of POLYSHIELD Knife edges provides.

Know in depth

At every step of production, we prioritize quality assurance to meet the highest industry standards. This dedication to quality ensures that our Poly Shield Knife Tips consistently excel in performance and longevity, offering a solution that stands up to the most demanding conditions and provides unmatched reliability.

Advantages:-)

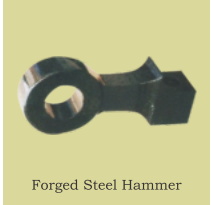

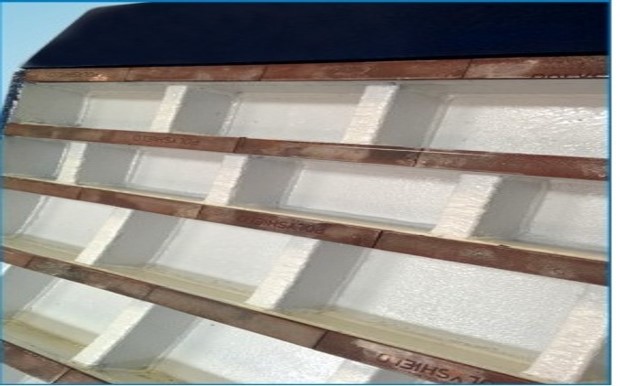

Shredder Hammers

We are manufacture a wide range of Mill House machinery ,equipments & components using quality tested raw materials, tailor made with high precision, accuracy & excellent workmanship as per the customer's drawing. We ensure the entire range is tested on well defined quality parameters, thereby meeting customer’s specific requirements besides providing the desired performance..

Know in depth

At our manufacturing facility, we take immense pride in producing an extensive array of Mill House machinery, equipment, and components, meticulously crafted from rigorously tested raw materials. Our commitment to precision, accuracy, and superior workmanship is evident in every product we create, with each item tailored to the exact specifications provided in the customer's drawings.