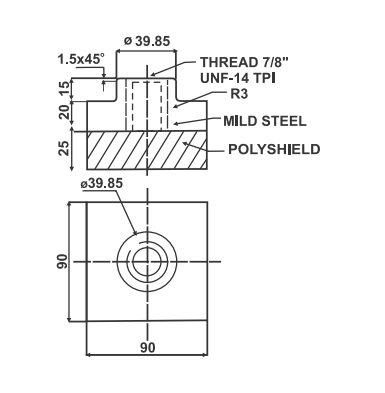

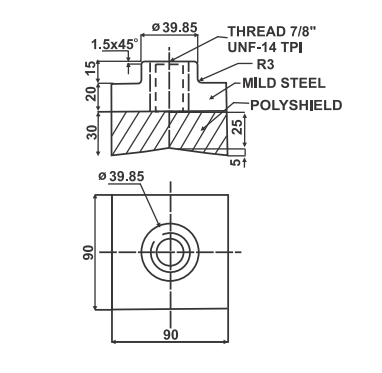

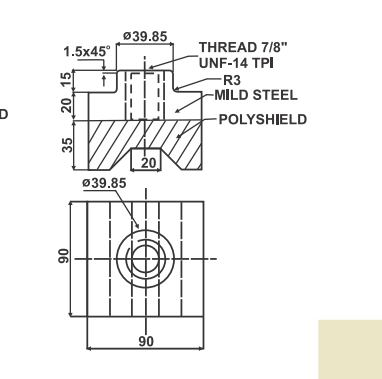

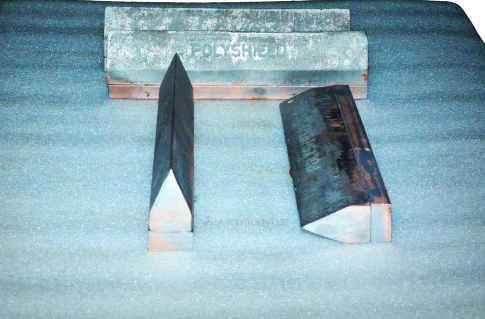

DETACHABLE HAMMER TIPS

The comprehensive range of POLYSHIELD detachable hammer tip manufactured by us is known for excellent impact & abrasion resistance properties & enhanced service life. These are bi-metallic composites having 700 bhn hardness and are bolted to the hammer shank using high tensile bolt. our range of hammer tips is available in various standard & custom-built sizes.

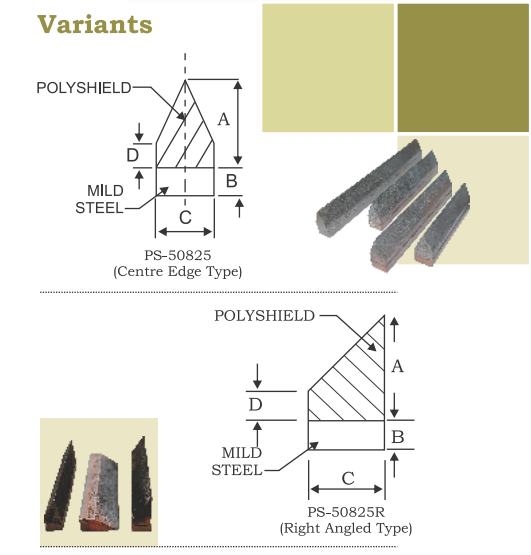

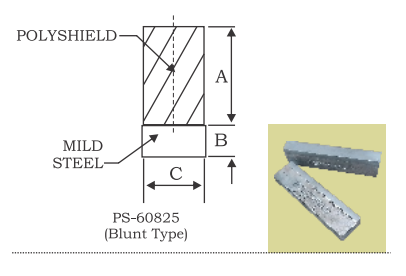

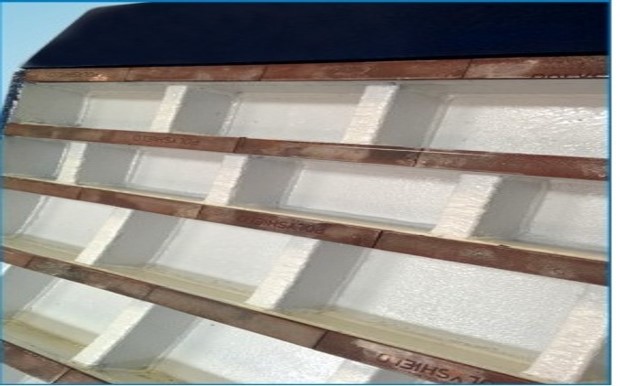

CANE KNIFE EDGES

Before the advent of the Shredder, cane knives were the only means of preparation & hardfaced knives were used for primary/secondary & main knifing of the sugar cane.

POLYSHIELD Knifes Edges have now mostly replaced the conventional hardfaced knives due to their versatility. The abrasion & impact resistant properties of POLYSHIELD Knife edges provides.

PROPERTIES:-)

SPECIFICATIONS

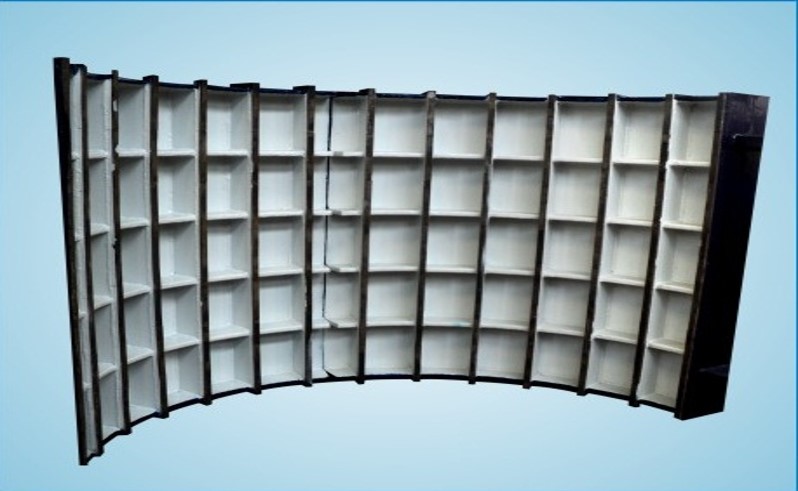

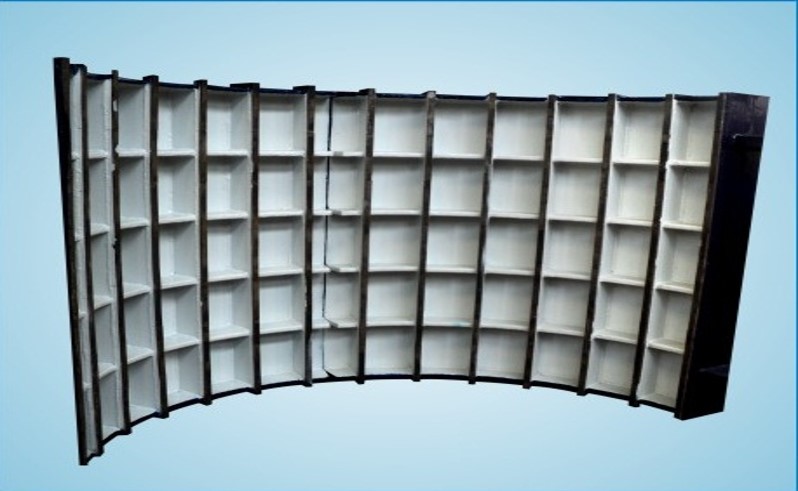

SHREDDER HAMMERS

We manufacture a wide range of Swing type hammers suitable for heavy duty shredding equipments viz. Shredder / Unigrator / Mincer / Fibrizer suitable for Walkers, Tongaat, Fives Cail, F & S, Krupp, Unice etc. for effective cane preparation. Use of quality & tested raw-materials, special hardfacing alloys, excellent workmanship has made our make hammers widely acceptable in the domestic & overseas markets. The crushing head of the hammer is either fitted with POLYSHIELD Detachable Tip or is heavily hardfaced with Chromium Carbide Electrode.

We manufacture these Hammers out of

• Mild Steel Plates

• Cast Steel

• Forged Steel

FEATURES

APPLICATION

Fixed Type Hammers

Fixed Type Hammers are fabricated using tested Mild Steel, precisely machined to the customer's drawing and hardfaced at wear prone areas. The crushing head of the hammer is either fitted with the POLYSHIELD detachable Tip (63 HRc) or is hardfaced with high grade abrasion resistant Chromium Carbide electrode having 55-58 HRc hardness. These Hammers are fitted to the Fibrizer / Unigrator / Mincer used for cane preparation.

Hardfaced Hammers

Prior to introduction & use of detachable tipped hammers, sugar mills have been using hardfaced hammers where the cutting edge is built up with chromium carbide electrodes. Here the worn out hammers are replaced with the standby set of hammers & the worn out ones are rebuilt. This process involves longer downtime, higher labour cost, expensive hardfacing besides low performance & increased power requirement due to round edges. These limitations made the sugar mills to happily switch over to the Tipped Hammers. However there are still few mills who continue to use hardfaced hammers satisfactorily